EPS foam cutting machine

The building industry is one of CROMA‘s main markets. Companies in this area are indeed the historical users of our machines and hot wire tools, which are essential to achieve elements in various fields.

Find out below the different uses of polystyrene and foams in this field of application, as well as some examples of representative creations.

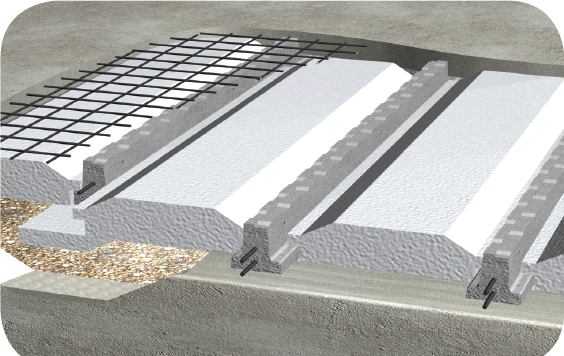

INSULATION:

Insulation boards, structural floor slabs… Due to its thermic insulation properties and its weight/volume ratio, the polystyrene (EPS and XPS) is highly present in this area.

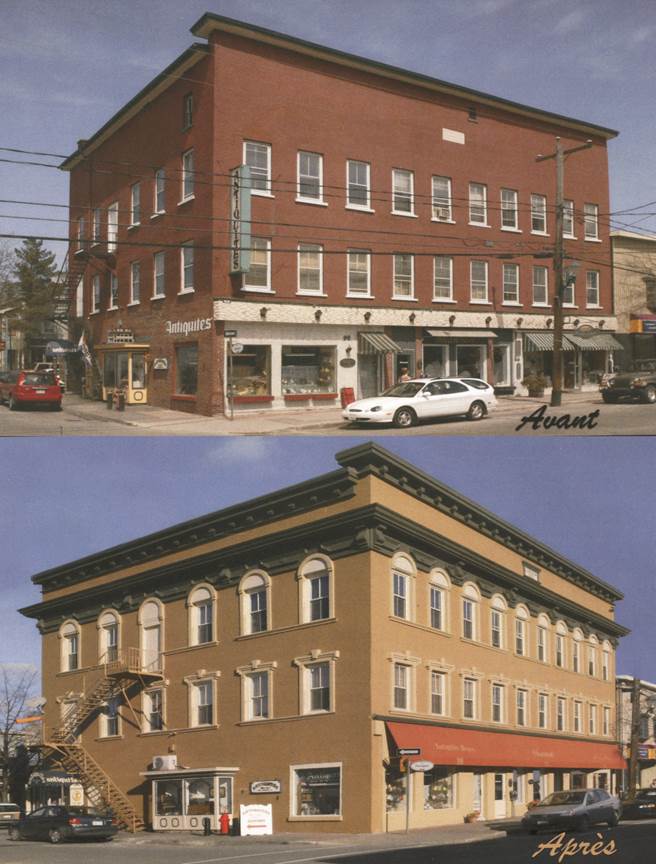

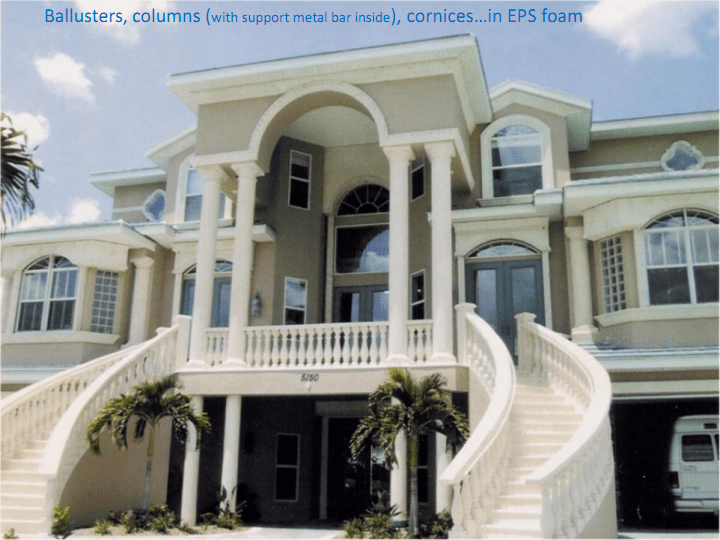

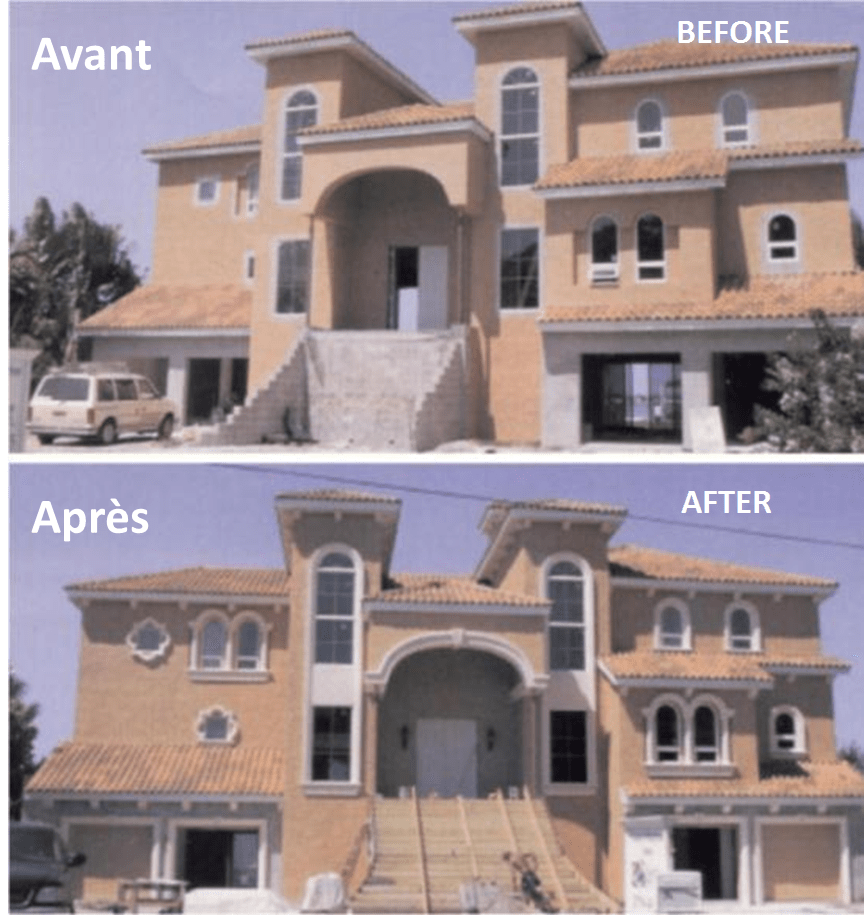

FACADE DECORATIONS:

With its lightness, the polystyrene is also much utilized to cover buildings with cornices, moldings or other decorative elements.

Here is an example of your ideal process optimization and improved productivity with CROMA’s product: The EPS foam cutting machine can process a hundred cornices in one flock within half an hour, then the parts are coated with the special resin, that CROMA sells as well, on an automatic coating machine also manufactured by CROMA.

See bellow some of our customers jobs and before/after examples.

PRECAST

Concrete molds, columns (some shapes achieved with our shapeable wire tool, sometimes associated to the horizontal lathe)

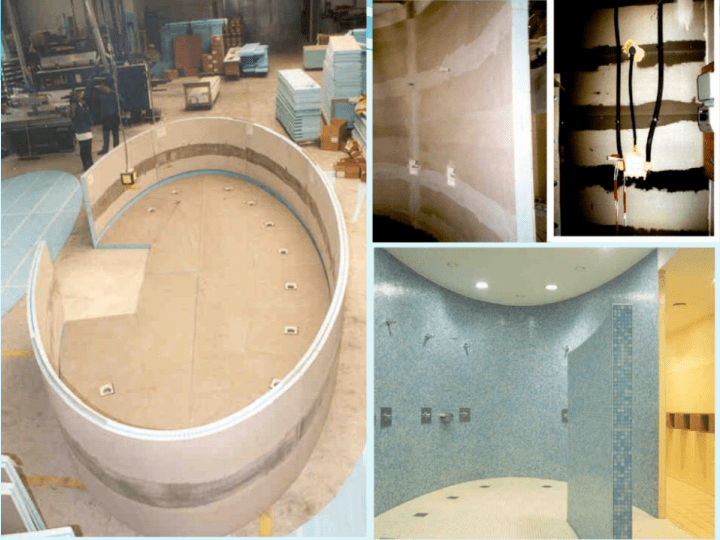

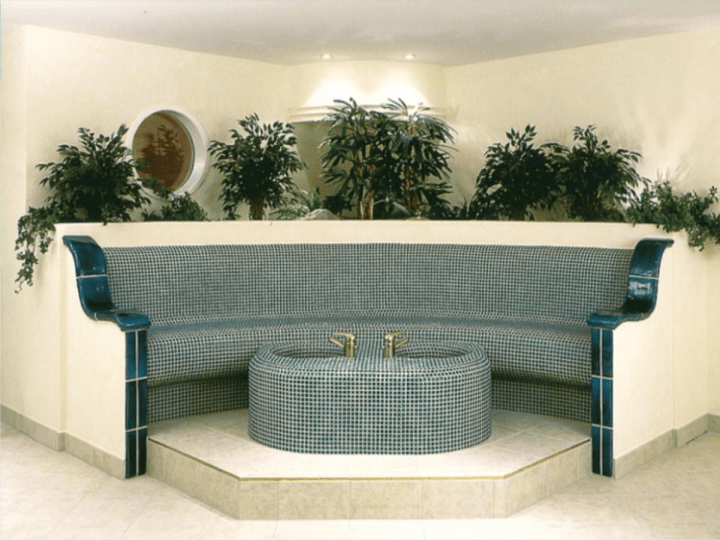

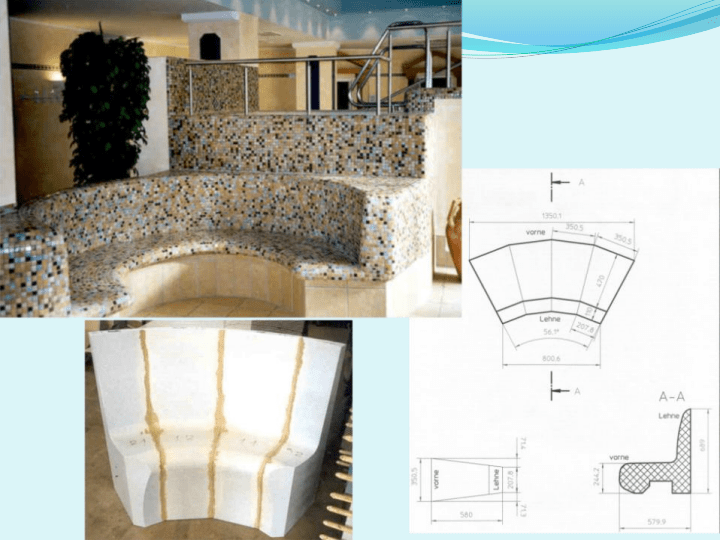

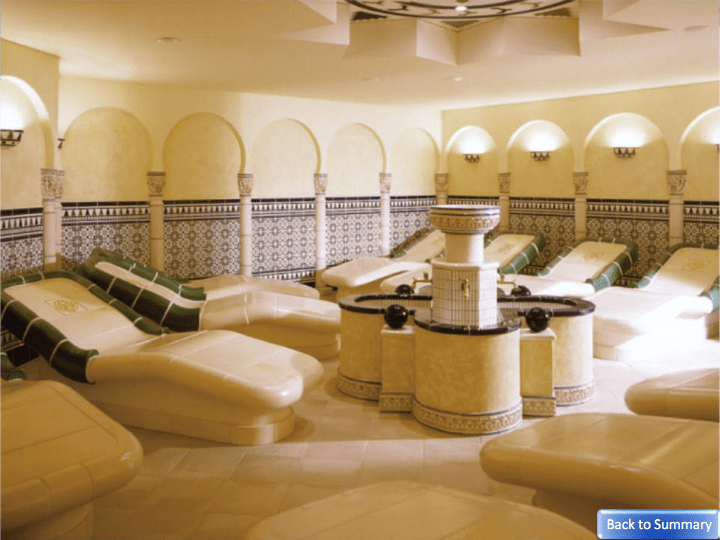

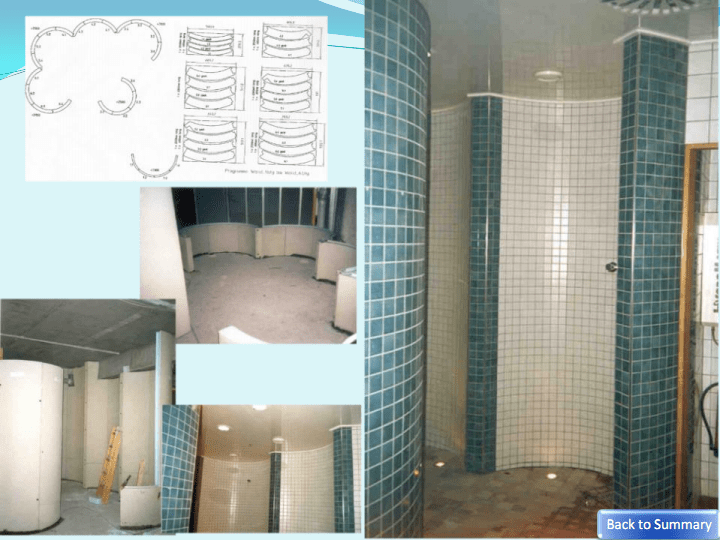

BATHROOM, SPA

Structural elements of the spas, often covered with tiles, or top covers of Jacuzzis generally contain EPS/XPS parts cut with our technology.

LANDSCAPE DESIGN ELEMENTS

Columns, low walls or other decorative elements

INTERIOR DESIGN:

Moldings and cornices are also well fitted for interior designs. With custom moldings, the size, shape and cost are no longer a problem thanks to the EPS foam cutting machine. The finished product is light, economical and easy to install.

Other materials such as wood or plaster are harder to process, particularly in large dimensions. Cornices or columns are more difficult to produce, heavier, more complex to install and, as a result, more expensive.

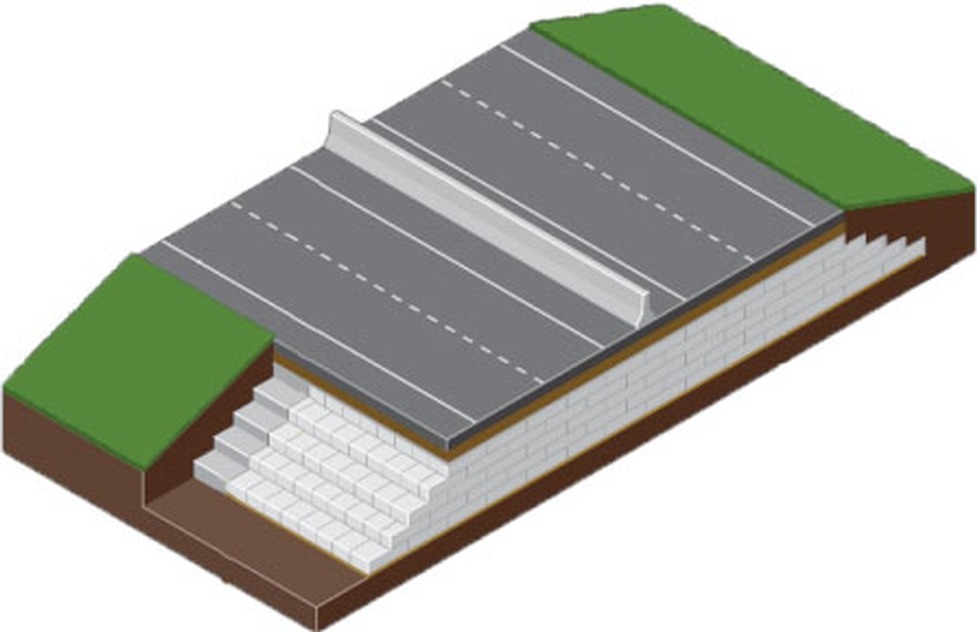

EMBANKMENT

Embankments achieved in expanded polystyrene, cut with hot wire for better material optimization.